行业新闻

Minebea Intec wins Patent of the Month

In May 2018, Hamburg Chamber of Commerce recognised a patent from Minebea Intec with its ‘Patent of the Month’ award. Patent number DE 10 2016 109 433 B4 describes a bolt sensor which allows bolt connections to be monitored remotely on bridges and at production facilities at risk of earthquakes for example. Patents like these are an important element of Minebea Intec’s research and development activities. They also play a key role in ensuring the company has a technological edge over its competitors.

2018年5月,德国汉堡商会授予将”本月专利”奖项授予了茵泰科的一项专利技术。此项DE 10 2016 109 433 B4号专利颁发给了一种螺栓传感器,它可以远程监测桥梁或者生产设施中螺栓的连接是否牢固。在处于地震等灾害性事故中,这样的远程监测非常有必要。专利技术是茵泰科的研发活动的重要组成部分,确保公司在竞争中保持技术领先。

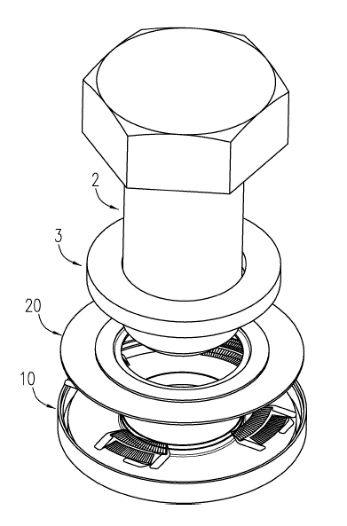

Washers are normally used to distribute the force of a bolt head or a nut over a greater area. However, Minebea Intec’s patented bolt sensor can do much more than this when, for example, it is integrated in bridges and production facilities; the sensor is installed between the bolt head and the nut, thus providing a detection system for any problems relating to strength.

垫片通常用于使螺栓或螺母的力平均分布到一个更大的受力面积中。而茵泰科的专利螺栓传感器能做得更多。在桥梁或者生产设施的建造中,在螺栓和螺母之间安装此传感器,可检测任何有关于力的问题。

Security system relies on resistors and pressure

电阻和压力的安全系统

The innovative Minebea Intec bolt sensor is installed between the bolt head and the nut. Piezoresistive resistors are connected to the inside of the washer. At least one of the resistors is exposed to the pressure from the bolt head and/or nut, and at least one is not exposed to any pressure. As soon as the bolt connection becomes loose, due to an earthquake for example, the bolt sensor can immediately detect the damage thanks to the change in resistance, and a repair or shutdown can then be initiated. In this way, the bolt sensor becomes part of a security system that communicates dangerous defects in real time. Minebea Intec is now planning to develop a prototype based on the patent recognised by Hamburg Chamber of Commerce – the date for the market launch has not yet been set.

创新的茵泰科螺栓传感器安装在螺栓和螺母之间,垫片中装有压阻电阻。其中至少有一个电阻会受到螺栓和/或螺母的力,也至少有一个电阻不会受到任何力。在例如地震等情况下,一旦螺栓连接松开,螺栓传感器作为安全系统的一部分,就会实时传递出有危险缺陷的信号。茵泰科现在正在计划研发这套被汉堡商会认可的系统样机,但是何时能投入市场尚未确定。

Patents secure an edge over the competition

在竞争中占据优势的专利

Minebea Intec continuously invests in the research and development of new technologies and products. Through this the company continues to support its customers in optimising the safety, reliability and efficiency of their processes. The global manufacturer of weighing and inspection technologies registers between five and ten patents each year. The patents are of particular significance to the company as they ensure an edge over the competition, help maintain its brand value and guarantee the latest technology for the customer.

茵泰科不断投资于研发新技术和新产品。公司一直支持其客户优化他们的过程安全、可靠和高效。茵泰科这家称重和检测技术的国际制造商每年都有5到10个专利技术得到登记。这些专利技术对于其市场竞争大有作用,同时也增加了其品牌价值,确保为客户提供最新技术。

Proper validation in the ongoing process

过程中验证

A further patent from Minebea Intec, number DE 20 2016 103 037 U1, describes a special device for validating metal detection systems; this is known as ‘True In-Process Validation’. Metal detection is considered a critical control point within food production. The patent relates to the special area of ‘closed conveyor systems’. If, for example, a production process involves pumping cornflakes or hot marmalade using pressure, the patented True In-Process Validation enables validation to be carried out during the ongoing process. This is done by introducing the test piece using an applicator via a small opening above the search coil, directly into the centre of the product flow. As the centre of the conveyor tube represents the most difficult point to detect, this method guarantees reliable detection and documentation. Once introduced, the test media falls with the product through the search coil area. If the metal part contained within is detected, it is ejected via a separator. If it is not detected, a previously installed collection grid ensures that it is not transported onward with the ‘goods flow’. The invention has already been implemented by Minebea Intec, and has been offered as an optional extra with the freefall metal detection system Vistus since 2016. Minebea Intec has further patents, including rotationally symmetrical diaphragms and mounting kits for load cells, for example. More detailed information about Minebea Intec can be found at www.minebea-intec.com.

茵泰科的另一个专利DE 20 2016 103 037 U1,是用于验证金属检测系统的设备,称之为”真正的过程中验证”。在食品生产中,金属检测是一个关键点。这个专利涉及到了”封闭的传输系统”。特别是在例如使用压力泵送玉米片或热果酱的生产中,”真正的过程中验证”专利就能帮助在这种正在进行的过程中进行验证。通过进样器将测试片导入检测线圈中,直接进入产品流。传送管的中央是检测的难点,这种方法能确保可靠的检测和记录。测试片进入后与产品一同通过检测线圈,金属部分被检测到的话,会通过剔除器剔除。如果没有被检测到,事先安装的收集网格也能保证测试片不会随着产品流被放过。这个茵泰科的专利已经于2016年作为Vistus下落式金属检测系统的一个选项被投入市场。茵泰科的专利还包括传感器旋转对称隔膜和安装套件等。更多茵泰科的信息,请访问www.minebea-intec.com.

Piezoresistive resistors are connected on the inside of the patented bolt sensor from Minebea Intec

茵泰科的专利螺栓传感器内安装有压阻电阻

For the freefall metal detection system Vistus, the test piece is introduced via an opening above the search coil into the centre of the product flow. Any test pieces not detected are reliably collected by a collection grid.

Vistus自由下落式金属检测系统中,测试片通过检测线圈上的开口进入产品流的中央。没有被检测出的测试片也可以通过收集网格可靠收集。